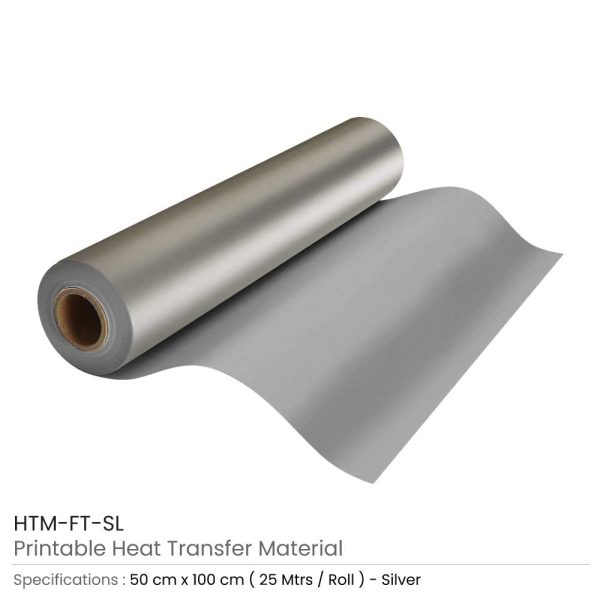

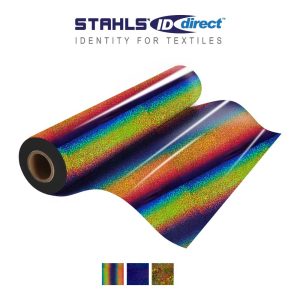

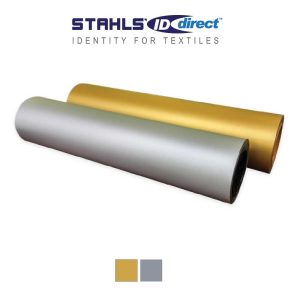

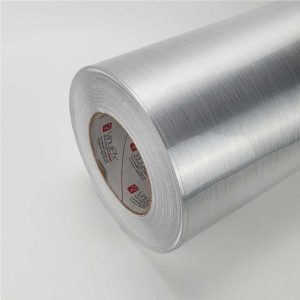

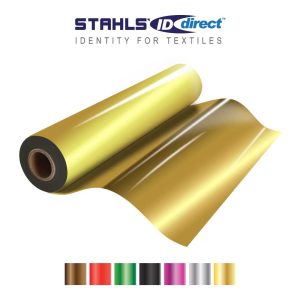

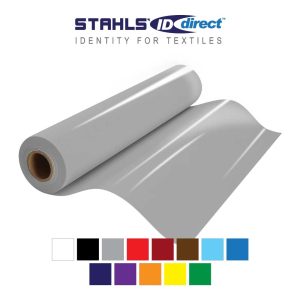

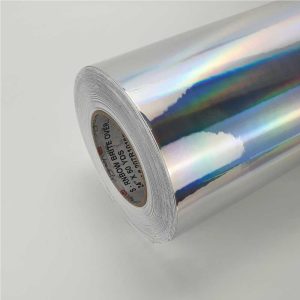

CAD COLOR FoilTEK Vinyl

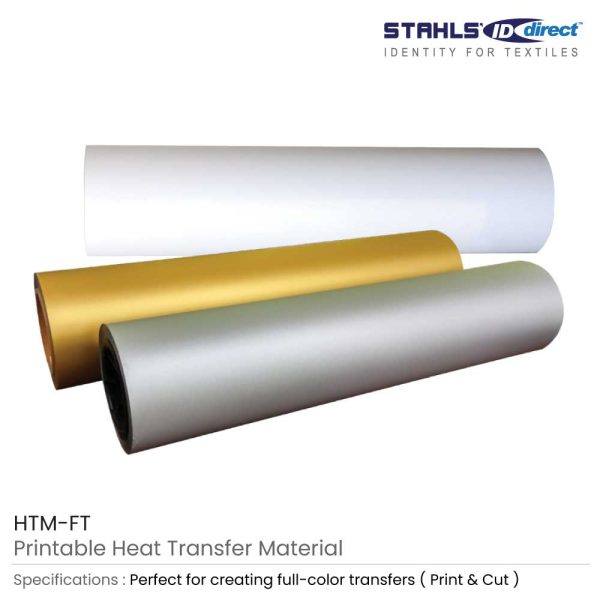

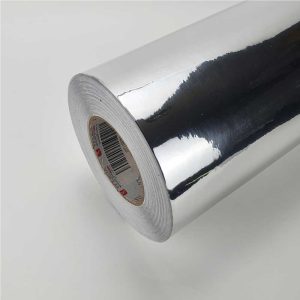

CAD COLOR FoilTEK Vinyl to its TEK series of printable heat transfer materials. Colors include gold, silver, and white metallic, and silver and gold shift. The material features four-way stretch and rebound, making it ideal for decorating high-performance sportswear, according to the company, and features Stahls’ patented STiX2 adhesive.

Recommended Fabrics

- Cotton

- Polyester

- Lycra® / Spandex

- Nylon

- Cordura®

- Leather

- Neoprene

- Description

- Application Instructions

- Packaging Details

Description

Stahls’ CAD COLOR Foil TEK Vinyl

Color in CAD To its TEK range of printable heat transfer materials, Foil TEK Vinyl. Silver and gold shift as well as gold, silver, and white metallic are among the colors. According to the business, the fabric has a four-way stretch, rebound, and Stahls’ unique STiX2 adhesive, making it perfect for embellishing high-performance sportswear.

Recommended Fabrics

- Cotton

- Polyester

- Lycra® / Spandex

- Nylon

- Cardura®

- Leather

- Neoprene

because the textile business uses a variety of textiles, weaves, coatings, and dyes.

Accessories Required

Kraft Paper Cover Sheet

EZ Weeder™ or Tweezers

Solutions Mask

Cutting Notes

For detailed designs

Premium Blade is recommended

You guarantee optimum blade depth when cutting, be sure to make test cuts.

Cutting too deeply will make it harder to weed or apply to the mask.

Care Instructions

The garment should be turned inside out for the best effects. Using a moderate detergent, do a warm or cold machine wash. Don’t use bleach. Avoid ironing a transfer immediately on. low-temperature tumble dry. Avoid dry cleaning.

Storage

Return the masking to the paper backing if the designs won’t be heat applied right away. Avert humid environments and sharp temperature swings.

Inks

Solvent

Eco-Solvent

Application Range

300°F is the typical application temperature.

Heat-sensitive materials can have the temperature lowered by up to 20 degrees.

TO PURCHASE THIS PRODUCT PLEASE CLICK HERE!

APPLICATION INSTRUCTIONS FOR

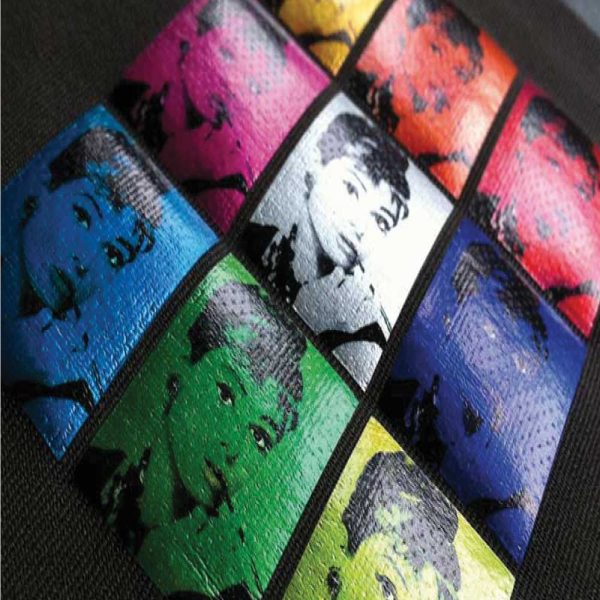

CAD COLOR PRINTABLE HEAT TRANSFER MATERIAL

FEED MATERIAL into plotter/cutter so that the media faces up

PRINT DESIGN in positive form.

CUT DESIGN If cutting through ink, let the print dry for 30 minutes otherwise you may cut immediately. Dry times may vary. Mask the material.

PRINT DESIGN in positive form. WEED away the excess media. If the design was cut immediately, the print must dry 30-60 minutes before proceeding.

PLACE MASK over the graphic, making sure to smooth out any air bubbles. REMOVE BACKING.

PREHEAT & POSITION Preheat garment for 10 seconds, prior to application. Position & place the cover sheet over the graphic.

HEAT APPLY Temp: 280-300°F; 138-150°C Time: 5 seconds Pressure: medium #6 on Hotronix® Tip: A Heat Printing Pillow or Print Perfect Pad is recommended for even pressure when working around zippers, buttons, heavy seams or mesh reversible jerseys.

PEEL MASK WARM

FINAL APPLICATION Place the cover sheet over the graphic and reseal for 5 seconds.

CUTTER GUIDELINES

CUTTER | BLADE | FORCE | OFFSET | SPEED

Roland SP-300 | 45° | 80-90g | .25 | 30cm/s

Roland VP-300 | 45° | 80-90g | .25 | 30cm/s

Roland XC-540 | 45° | 80-90g | .25 | 30cm/s

Roland GX-24 | 45° | 80-90g | .25 | 30cm/s

Additional information

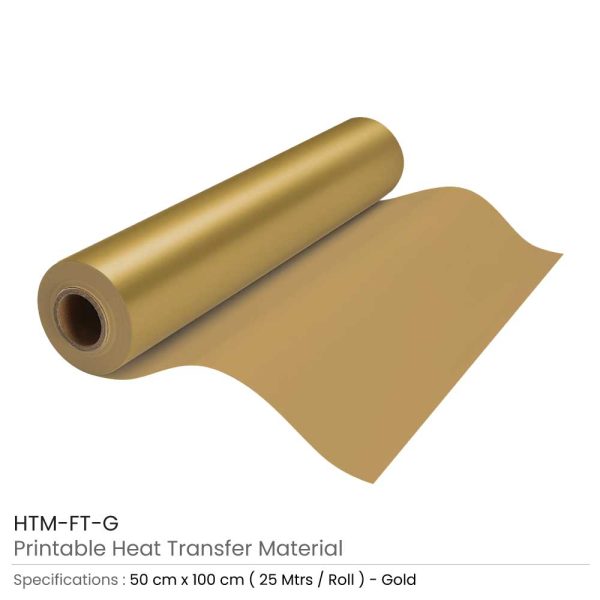

| Dimensions | 50 × 100 cm |

|---|---|

| HTM-FT | Gold, Silver, White |